0102030405

How to weld LED light strip?

2024-07-08 17:30:02

Detailed explanation of lamp strip welding skills

1. Basic process of lamp strip welding

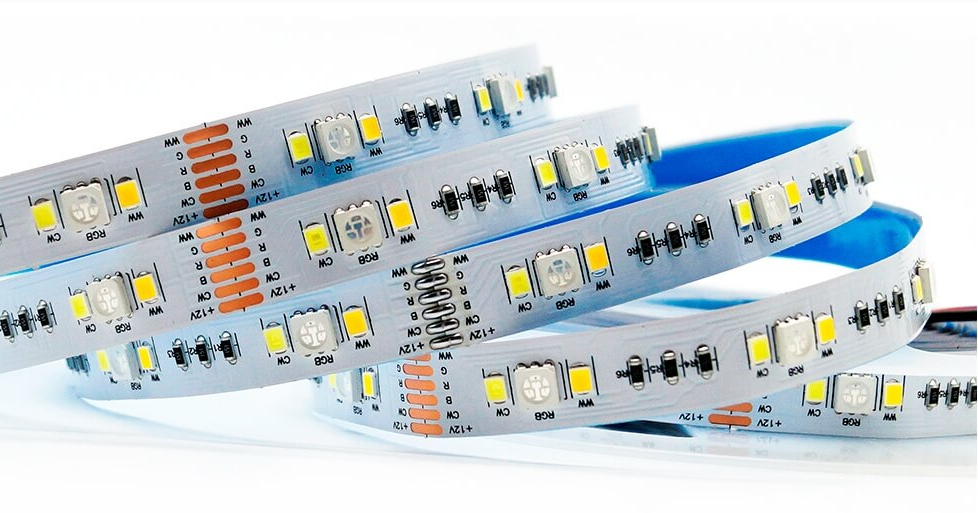

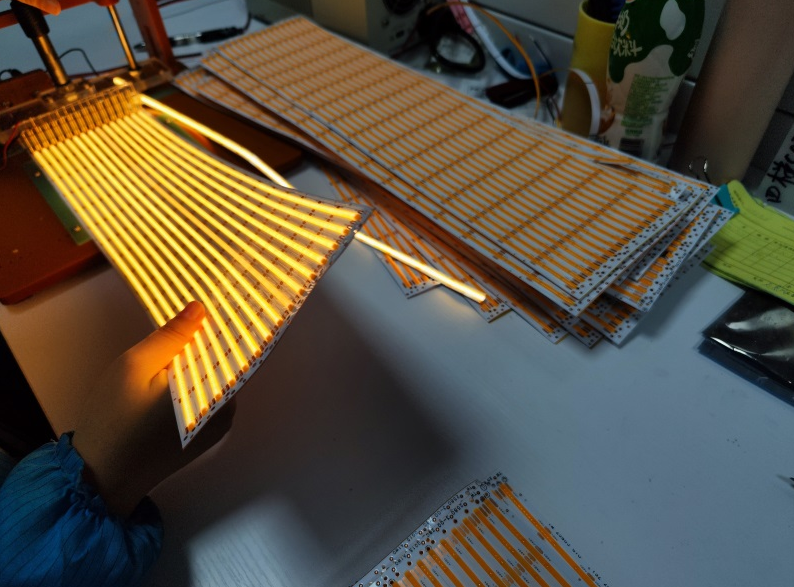

Light strips are generally composed of multiple independent LED lamp beads, so when welding the light strip, each LED lamp bead needs to be connected. Specific steps are as follows:

1. First, prepare welding tools, including soldering iron, solder wire, screwdriver, scissors, etc.

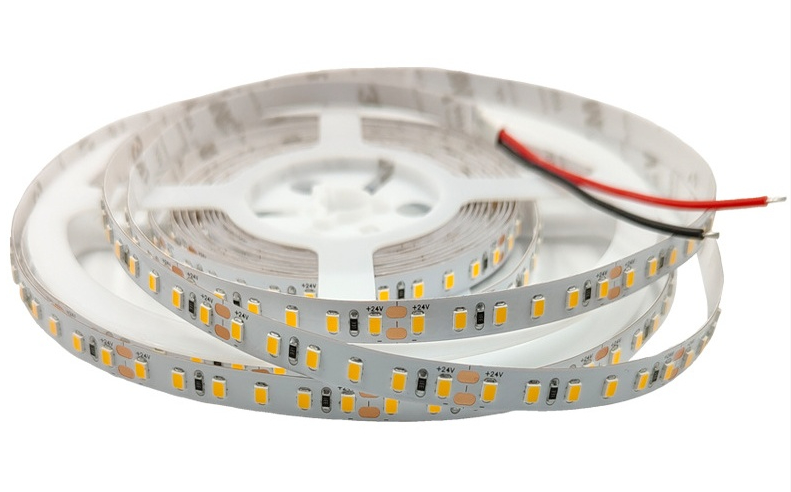

2. Weld the terminal wires at both ends of the light strip to the power cord. This is the most important step of the light strip. When welding, pay attention to the fact that the polarity of the terminal wire and the power wire should be consistent, that is, the positive and negative electrodes cannot be connected reversely.

3. Connect the positive and negative poles of each LED lamp bead. When connecting, first use scissors to cut off the protective layers at both ends of the LED lamp beads to expose the metal contacts. Then use a screwdriver to gently open the connector, and insert the anode and cathode of the LED lamp beads into the connectors respectively.

4. Finally, use a soldering iron to solder the connector to the LED lamp beads.

2. Precautions

1. When welding light strips, be sure to pay attention to insulation treatment to avoid short circuit or leakage in the welding line, which may cause damage to electronic components.

2. When welding the light strip, be sure to choose the appropriate welding temperature. Too high a welding temperature will burn out the LED lamp beads, and too low a welding temperature will not achieve good welding results.

3. In order to ensure the welding quality, it is recommended to use better quality solder wire and soldering iron. And when welding, the stability should be strengthened to avoid unnecessary shaking.

4. When trimming LED light strips, be sure to use pliers instead of scissors, otherwise unnecessary damage will occur.

5. It is recommended to conduct a test after the welding is completed to ensure that the connection is good and the circuit is stable to avoid unnecessary trouble.

3. Commonly used tools

1. Electric soldering iron: used to melt solder and solder components and circuits together.

2. Solder wire: used to heat wires, components and solder joints on circuits. It is the most commonly used material for soldering electronic components.

3. Scissors: used for cutting light strips, cutting solder wire, etc.

4. Screwdriver: used to disassemble the LED lamp bead connector to facilitate the connection of the positive and negative poles of the LED lamp bead.

4. Summary

Through the introduction of this article, I hope everyone will understand the welding process and precautions of light strips. Proficient in the welding technology of light strips, you can not only simply DIY your favorite home elements, but also bring bright lights to your life.